I thought it might be a good idea to bring everything I've done together into one thread, sort of a project thread.

I'll start from the beginning and I'll update it often to bring it all up to date. Any comments welcome, but remember that these first posts are for work I did a good while ago.

November 2009.

Bought the car. It's a Nov 2000 facelift model, LMB, pretty much standard. Car had seen better days but was mechanically sound and seeing I like palying with cars, it was ideal for me.

I had to sort the headlight adjusters as soon as I had it, I mentioned this here in my first post on m5board!:

http://www.m5board.com/vbulletin/e39-m5-e52-z8-discussion/149580-can-someone-help-i-need-headlight-part.html

January 2010.

Bought some 13cm speakers for the rear of the car, thinking they'd make a world of difference. I was very wrong. Car has the ordinary business radio and no amp, subs or anything good in the sounds department. Seed sown, remember this for later!

Very soon after I modified the wiper arms to take e60 flat blades, I like how these blades work. I followed a guide on the bmw5 forum here:

http://forum.bmw5.co.uk/topic/22408-aero-wiper-project-now-finished-with-how-to-guide/page__st__30

February 2010.

During this initial time I also had to:

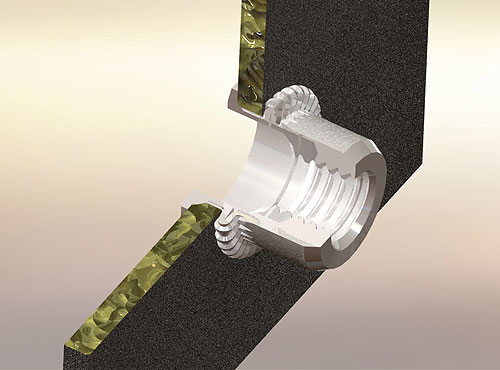

Strip down and repair the mirrors so that they folded, the little internal gears had worn so I managed to get hold of some broken 2nd hand mirrors and strip them down for the bits.

I also discovered that the mirror/window control switch had a burnt out chip in it, sorted that out as well.

Also discovered that you can reverse the wing mirror folding action by simpy swapping the two motor wires in the connector, they are a solid blue wire and a solid white wire (by solid I mean only one colour, there are no trace colours). A bit on this here:

http://www.m5board.com/vbulletin/e39-m5-e52-z8-discussion/172186-auto-fold-mirrors-new-module-help-please.html

Through sheer luck I got hold of and fitted an alcantara headlining and associated bits, very nice.

Fitted a glass sunroof panel instead of the steel one. This meant that I took out the roof lining again, as I wanted to sort a 'drag' fault to the sunroof mechanism, it was a slider of sorts that had broken. Learnt a lot about the sunroof mechanism, DIS was handy in re-setting the control.

I got another key and discovered all about 'key memory' which is a pretty cool feature that allows many options/settings to be assigned differently to different keys. So, I would have my seat, steering wheel, heater, radio and maybe a few other quirky options (bongs, closure etc) and my wife would have her settings on her key (but she never drives it, but that's not the point!).

I was surpised that the dealer would have wanted about £100 to set this to 'on' using the diag, I did it myself with my own one for free! That was a good feeling.

...

I'll start from the beginning and I'll update it often to bring it all up to date. Any comments welcome, but remember that these first posts are for work I did a good while ago.

November 2009.

Bought the car. It's a Nov 2000 facelift model, LMB, pretty much standard. Car had seen better days but was mechanically sound and seeing I like palying with cars, it was ideal for me.

I had to sort the headlight adjusters as soon as I had it, I mentioned this here in my first post on m5board!:

http://www.m5board.com/vbulletin/e39-m5-e52-z8-discussion/149580-can-someone-help-i-need-headlight-part.html

January 2010.

Bought some 13cm speakers for the rear of the car, thinking they'd make a world of difference. I was very wrong. Car has the ordinary business radio and no amp, subs or anything good in the sounds department. Seed sown, remember this for later!

Very soon after I modified the wiper arms to take e60 flat blades, I like how these blades work. I followed a guide on the bmw5 forum here:

http://forum.bmw5.co.uk/topic/22408-aero-wiper-project-now-finished-with-how-to-guide/page__st__30

February 2010.

During this initial time I also had to:

Strip down and repair the mirrors so that they folded, the little internal gears had worn so I managed to get hold of some broken 2nd hand mirrors and strip them down for the bits.

I also discovered that the mirror/window control switch had a burnt out chip in it, sorted that out as well.

Also discovered that you can reverse the wing mirror folding action by simpy swapping the two motor wires in the connector, they are a solid blue wire and a solid white wire (by solid I mean only one colour, there are no trace colours). A bit on this here:

http://www.m5board.com/vbulletin/e39-m5-e52-z8-discussion/172186-auto-fold-mirrors-new-module-help-please.html

Through sheer luck I got hold of and fitted an alcantara headlining and associated bits, very nice.

Fitted a glass sunroof panel instead of the steel one. This meant that I took out the roof lining again, as I wanted to sort a 'drag' fault to the sunroof mechanism, it was a slider of sorts that had broken. Learnt a lot about the sunroof mechanism, DIS was handy in re-setting the control.

I got another key and discovered all about 'key memory' which is a pretty cool feature that allows many options/settings to be assigned differently to different keys. So, I would have my seat, steering wheel, heater, radio and maybe a few other quirky options (bongs, closure etc) and my wife would have her settings on her key (but she never drives it, but that's not the point!).

I was surpised that the dealer would have wanted about £100 to set this to 'on' using the diag, I did it myself with my own one for free! That was a good feeling.

...