Yesterday I bit the bullet and decided to sort out the pixel problem on my dash.

My car is definitely out of warranty and has no 3rd party warranty either, so it was up to me to sort this out somehow. Obviously, it would have been nice to get a new one from the dealer, but I have a feeling that they would not have entertained the thought!

A couple of months ago I bought a repair kit off ebay for £26. It's the same guy as BMW LCD pixelhiba javítás, autóműszer autóelektronika diagnosztika. . The kit consisted of a replacement plastic ribbon to go from the circuit board to the LCD and an instruction pamphlet.

I didn't jump to it as I saw that the replacement ribbon had no adhesive at all. This worried me a bit as I knew that the oem ribbon is bonded at both ends. I thought about it and researched it for a while and it turns out that the ribbon does not need to be bonded to the circuit board (nor the LCD).

Back to yesterday:

I removed and stripped the cluster down. I had to drill four 5mm sized holes to gain access to the four Torx (Tx 9) screws that hold the white plastic LCD carrier to the circuit board (and also clamp the ribbon, applying pressure to it).

This was quite a daunting task but it turns out that it's not so difficult (careful measuring/marking and bending back the dial backing - grey on mine). Also, from what I can see, there are no ill effects to the lighting on the cluster after doing so.

Drilling means that the dial needles do not need to be removed; from what I understand this is no bad thing as when the needles are pulled up, they tend to pull the spindle up from the motor and ruin the return spring in the process, another problem and cost - this is avoidable.

In the end I had the dials and the bare lcd hanging underneath. I took this back into the car to check where the connection was bad (circuit board or LCD). I found that the problem was at the circuit board end of the ribbon, but the pixel loss had got much worse.

I reckon that just moving the LCD section, thus flexing the plastic ribbon, had cracked the tracks in the ribbon. There was no doubt that just flexing things had made them much worse.

Some people say that increasing the pressure between the circuit board and the ribbon solves the problem. Moving things about to enable you to add packing (eg thin strip of card) might end up making it worse, so it's likely that the ribbon would have to be renewed - this was the case for me.

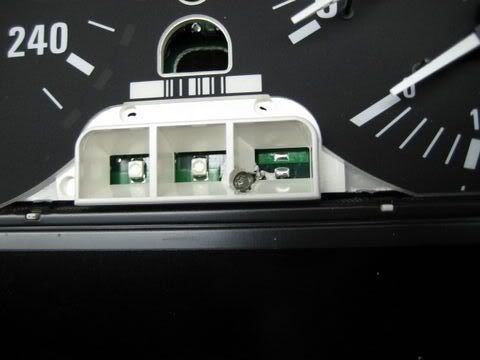

All traces of the oem adhesive had to cleaned off the board and LCD, some electrical contact cleaner and my nail did the trick. You can see the cleaned contacts in the following picture and I do apologise for the slightly blurred image.

![Image]()

Aligning the ribbon with the LCD section was probably the most awkward step as you can't easily see the 'tracks' on the LCD glass (holding it an angle to the ight helped). Once that was sorted, the ribbon would also align with the circuit board contacts. The ribbon is held in place by the LCD clip - no adhesive required.

The ribbon was then folded up and sat quite neatly in the white lcd carrier, in the correct position to be fitted to the circuit board. I added a couple of strips of photo paper behing the rubber pressure pads, to increase the pressure by a bit, though I suspect this wasn't really necessary.

The LCD assembly was then re-fitted (using the four Tx9 screws) and the unit returned to the car for a test. It was a great relief to see everything working properly under 'Test 2' in the secret menu. See picture:

![Image]()

Everything was bolted and clipped back together and the instrument cluster finally re-fitted to the car.

If anyone has the pixel problem and don't want to send their instrument cluster away, then it is possible to renew the ribbon yourself cheaply. All you need is a lot of patience and some confidence.

As long as you don't break anything, if you fail to get the pixels to work, you still have the option of sending it away.

I hope this helps anyone who's considering undertaking the job themselves.

My car is definitely out of warranty and has no 3rd party warranty either, so it was up to me to sort this out somehow. Obviously, it would have been nice to get a new one from the dealer, but I have a feeling that they would not have entertained the thought!

A couple of months ago I bought a repair kit off ebay for £26. It's the same guy as BMW LCD pixelhiba javítás, autóműszer autóelektronika diagnosztika. . The kit consisted of a replacement plastic ribbon to go from the circuit board to the LCD and an instruction pamphlet.

I didn't jump to it as I saw that the replacement ribbon had no adhesive at all. This worried me a bit as I knew that the oem ribbon is bonded at both ends. I thought about it and researched it for a while and it turns out that the ribbon does not need to be bonded to the circuit board (nor the LCD).

Back to yesterday:

I removed and stripped the cluster down. I had to drill four 5mm sized holes to gain access to the four Torx (Tx 9) screws that hold the white plastic LCD carrier to the circuit board (and also clamp the ribbon, applying pressure to it).

This was quite a daunting task but it turns out that it's not so difficult (careful measuring/marking and bending back the dial backing - grey on mine). Also, from what I can see, there are no ill effects to the lighting on the cluster after doing so.

Drilling means that the dial needles do not need to be removed; from what I understand this is no bad thing as when the needles are pulled up, they tend to pull the spindle up from the motor and ruin the return spring in the process, another problem and cost - this is avoidable.

In the end I had the dials and the bare lcd hanging underneath. I took this back into the car to check where the connection was bad (circuit board or LCD). I found that the problem was at the circuit board end of the ribbon, but the pixel loss had got much worse.

I reckon that just moving the LCD section, thus flexing the plastic ribbon, had cracked the tracks in the ribbon. There was no doubt that just flexing things had made them much worse.

Some people say that increasing the pressure between the circuit board and the ribbon solves the problem. Moving things about to enable you to add packing (eg thin strip of card) might end up making it worse, so it's likely that the ribbon would have to be renewed - this was the case for me.

All traces of the oem adhesive had to cleaned off the board and LCD, some electrical contact cleaner and my nail did the trick. You can see the cleaned contacts in the following picture and I do apologise for the slightly blurred image.

Aligning the ribbon with the LCD section was probably the most awkward step as you can't easily see the 'tracks' on the LCD glass (holding it an angle to the ight helped). Once that was sorted, the ribbon would also align with the circuit board contacts. The ribbon is held in place by the LCD clip - no adhesive required.

The ribbon was then folded up and sat quite neatly in the white lcd carrier, in the correct position to be fitted to the circuit board. I added a couple of strips of photo paper behing the rubber pressure pads, to increase the pressure by a bit, though I suspect this wasn't really necessary.

The LCD assembly was then re-fitted (using the four Tx9 screws) and the unit returned to the car for a test. It was a great relief to see everything working properly under 'Test 2' in the secret menu. See picture:

Everything was bolted and clipped back together and the instrument cluster finally re-fitted to the car.

If anyone has the pixel problem and don't want to send their instrument cluster away, then it is possible to renew the ribbon yourself cheaply. All you need is a lot of patience and some confidence.

As long as you don't break anything, if you fail to get the pixels to work, you still have the option of sending it away.

I hope this helps anyone who's considering undertaking the job themselves.